AW pneumatic actuator

AW pneumatic actuator

Working environment temperature:

Basic: -20 ℃ ~ 90 ℃

High temperature: -20 ℃ ~ 180 ℃

Low temperature: -40 ℃ ~ 90 ℃

Angle of rotation: 90 ° ~ ± 5 °

Air source interface: AW13-G1 / 4, AW17-G3 / 8, AW20 ~ AW40-G1 / 2

First, AW pneumatic actuator product overview

AW Pneumatic Actuator Pneumatic Actuator for 90 ° swivel (1/4 turn) valves. Such as ball valves, butterfly valves, plug valves and so on. This product is designed and manufactured using JIS standards, and the two valves with the Department of the international standards ISO5211.AW/AW-S pneumatic actuator drive mass production, excellent performance, quality and stability.

Second, AW pneumatic actuator model specifications

| Model specifications | Air pressure (Mpa) | ||||

|---|---|---|---|---|---|

| 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | |

| AW13 | 515 | 620 | 770 | 930 | 1080 |

| AW17 | 950 | 1270 | 1590 | 1910 | 2230 |

| AW20 | 2150 | 2870 | 3580 | 4300 | 5020 |

| AW25 | 3360 | 4480 | 5600 | 6720 | 7850 |

| Aw28 | 5150 | 6860 | 8580 | 10300 | 12020 |

| AW35 | 10120 | 13500 | 16870 | 20250 | 23620 |

| AW40 | 13220 | 17630 | 22040 | 26450 | 30860 |

| AW50 | 22460 | 29950 | 37440 | 44930 | 52420 |

| AW60 | 47300 | 63070 | 78840 | 94610 | 110380 |

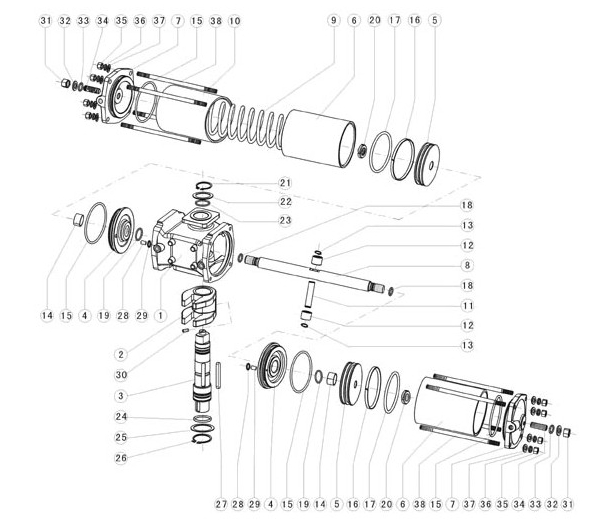

Third, AW pneumatic actuator decomposition diagram

Four, AW pneumatic actuator parts description

| Serial number | name | Quantity | Serial number | name | Quantity | Serial number | name | Quantity | Serial number | name | Quantity |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Box | 1 | 11 | Pin | 1 | twenty one | Retaining ring | 1 | 31 | fasten the screw nut | 2 |

| 2 | Fork | 1 | 12 | Roll sleeve | 2 | twenty two | Reducing washers | 1 | 32 | Flat Washers | 2 |

| 3 | Shaft | 1 | 13 | Retaining ring | 2 | twenty three | O-ring | 1 | 33 | O-ring | 2 |

| 4 | Partition | 2 | 14 | Oil-free bearings | 2 | twenty four | O-ring | 1 | 34 | Adjust the screw | 2 |

| 5 | piston | 2 | 15 | O-ring | 2 | 25 | Reducing washers | 1 | 35 | Nut | 8 |

| 6 | Cylinder | 2/3 | 16 | Guide ring | 2 | 26 | Retaining ring | 1 | 36 | Elastic washers | 8 |

| 7 | Cylinder head | 2 | 17 | O-ring | 2 | 27 | Flat key | 1 | 37 | Flat Washers | 8 |

| 8 | Piston rod | 1 | 18 | O-ring | 2 | 28 | O-ring | 2 | 38 | Studs | 8, |

| 9 | spring | 1/2/4 | 19 | O-ring | 2 | 29 | Positioning pin | 2 | 39 | ||

| 10 | Spring cylinder | 1 | 20 | fasten the screw nut | 2 | 30 | Set screws | 1 | 40 |

Fifth, AW pneumatic actuator main performance characteristics

1, AW pneumatic actuator is divided into double-acting, single-acting (spring reset), two separate cylinder. Easy to manufacture large-size cylinder. Meet a variety of large rotating valve needs.

2 , the output torque, flexible balance of action, the cylinder wall and the piston shaft hard chrome plated, with good anti-friction, all moving parts with oil-free lubrication between the shaft and the guide ring to reduce the friction coefficient, to extend the service life , AW pneumatic actuator U -curve characteristics of the output torque more suitable for large-diameter ball valve, butterfly valve.

3 , the sliding device made of low friction material, to avoid the direct contact of metal and metal.

4, the bottom of the fixed hole to facilitate the actuator and valve connection and make it aligned, in line with ISO5211 / DIN3337standards.

5 , the bottom of the mounting hole for the square, easy to connect with the stem and can be rotated 45 ° corner installation.

6 , the rotation angle: double-acting = 90 °, single-acting = 90 ° adjustable from both ends of the angle of ± 5 °.

7 , the working environment temperature: -20 ℃ ~ 80 ℃.

8 , gas source: filter, dry or lubricated clean air, the minimum pressure 0.1Mpa , the maximum pressure 1Mpa .

9 , the basic design: pneumatic dual-cylinder double-piston fork transmission. Model AW = double acting; type AWS = single acting(spring return) .

10 , AW series of pneumatic devices for 90 ° rotation ( 1/4 turn) of the valve. Such as ball valves, butterfly valves, plug valves and so on. This product is designed and manufactured using JIS standards, and valve connections using the international standard ISO5211 .

| Main dimensions - PN25 (25bar) | |||||||||

| model | AWD13 AWE13 | AWD17 AWE17 | AWD20 AWE20 | AWD25 AWE25 | AWD28 AWE28 | AWD35 AWE35 | AWD40 AWE40 | AWD50 AWE50 | AWD60 |

| L | 627 | 850 | 1158 | 1158 | 1448 | 1880 | 1880 | 2350 | 2800 |

| L1 | 850 | 1120 | 1495 | 1630 | 1955 | 2520 | 2520 | 3280 | / |

| H | 228 | 275 | 326 | 326 | 396 | 440 | 490 | 600 | 700 |

| H1 | 200 | 270 | 350 | 375 | 460 | 545 | 570 | 680 | 820 |

| H2 | 46 | 55 | 67 | 67 | 80 | 116 | 116 | 144 | 172 |

| H3 | 7 | 8 | 12 | 12 | 11 | / | / | / | / |

| H4 | / | / | / | / | / | / | 54 | 54 | 54 |

| A | 42 | 50 | 64 | 64 | 85 | / | / | / | / |

| B | 28 | 34 | 44 | 44 | 55 | / | / | / | / |

| C | 85 | 112 | 137 | 137 | 160 | 203 | 203 | 230 | 256 |

| D | 95 | 143 | 157 | 157 | 170 | / | / | / | / |

| C1 | 70 | 70 | 100 | 100 | 100 | 180 | 180 | 195 | 234 |

| D1 | 35 | 50 | 60 | 60 | 60 | 60 | 60 | 80 | 60 |

| Z-M1 | 2-M8 | 2-M10 | 2-M10 | 2-M10 | 2-M10 | 4-M6 | 4-M6 | 4-M6 | 4-M6 |

| E | 80 | 120 | 140 | 140 | 220 | 220 | 220 | 280 | 360 |

| F | 34 | 48 | 60 | 60 | 70 | 105 | 105 | 120 | 140 |

| G | 132 | 190 | 232 | 232 | 318 | 350 | 350 | 400 | 500 |

| G1 | 100 | 160 | 200 | 200 | 280 | 300 | 300 | 350 | 450 |

| Z-M2 | 4-M16 | 8-M16 | 8-M16 | 8-M16 | 8-M20 | 8-M24 | 8-M24 | 12-M24 | 12-M27 |

| b | 10 | 14 | 18 | 18 | 20 | 28 | 28 | 32 | 36 |

| T | 37.3 | 51.8 | 64.4 | 64.4 | 74.9 | 117.8 | 117.8 | 127.4 | |

| Air source interface | 4-G1 / 4 | 4-G3 / 8 | 4-G1 / 2 | 148.5 | |||||