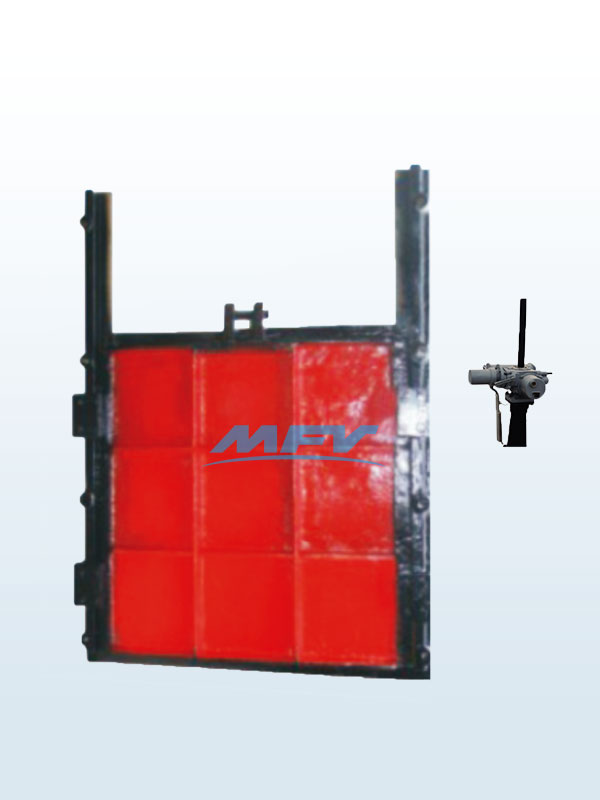

Inlaid copper cast iron square gate

Inlaid copper cast iron square gate

Nominal diameter: DN200 ~ 2500mm

Pressure range: ≤ 0.1Mpa

Operating temperature: -20 ℃ ~ 120 ℃

Drive mode: hand wheel, hand type, Flashlight dual hoist

Flange standard: GB / T9115-98

Connection dimensions: GB2555-81PN2.5

Detection: GB / T13927-92

First, ZMQF- cast iron square copper gate range:

ZMQF-cast iron copper square gate, also known as cast iron gate, square gate, is mainly used for water supply and drainage, flood control, irrigation, water conservancy, hydropower project, used to cut off, clear the water flow or play a role in regulating the water level, And the United States AWWA standard design and production. It adopts a unique outer arc design, reasonable structure, uniform force, the use of high-quality gray cast iron or ductile iron, stainless steel, sealing surface sealing copper or rubber, and after precision machining with research to achieve a plane contact seal, Sealing performance, when the sealing water stop performance can be adjusted by the wedge device to be resolved.

Second, ZMQF- cast iron copper square gate Product Overview:

1, ZMQF-cast iron copper square gate from the door frame, gate, rail, seal, screw drive, hanging nut / lifting lug and adjustable sealing mechanism and other components, including the door frame and gate are made of high quality gray cast iron or Ductile iron made of steel, the guide rail symmetrical arrangement and positioning pins with stainless steel bolts on both ends of the door frame connection (for small and medium-sized gate, the guide rail can be poured into one with the door frame), the guide rail length is generally the gate fully open height 1 / 2 ~ 1/3, so the overall structure of high strength, high rigidity, wear resistance, corrosion resistance, pressure capacity.

2, through the wedge wedge device to achieve sealing, sealing material for the copper alloy or rubber, and after precision processing with research, so good sealing.

3, using embedded steel or embedded bolt installation, installation, commissioning, use, easy maintenance, long service life.

4, complete variety specifications, wide adaptability.

5, with the hoist supporting the use of the gate for the work part, hoist for the gate to open and close the implementation of the part, hoist by manpower, motor or pneumatic, hydraulic drive gear drive gear, worm and other running, driven Drive nut or screw to rotate the brake shaft for vertical movements, so as to open or close the gate, to achieve the purpose of water, water or water level.

Third, ZMQF- cast iron copper side gate Main technical performance parameters:

1, Model and specification: Square gate: Ming rod type ZMQF DN200 ~ DN2500mm

2, ZMQF-cast iron copper square gate Main performance indicators:

a) The gate seal surface with the gap ≤0.1 mm, seal seat thickness greater than 10 mm.

b) sealing surface per meter length of water seepage: Forward ≤ 0.7L / min · m reverse ≤ 1.25L / min · m

c) Nominal pressure ≤ 0.1Mpa; Seal test pressure 0.1Mpa.

d) Working environment: temperature -20 ℃ ~ 120 ℃ Humidity: 95% Working medium: water and sewage PH value: 5 ~ 10

e) Installation position: Normal water, in a vertical state.

f) Maximum working head: Unidirectional pressure: Forward: 10m Reverse: 5m Bidirectional pressure: both 10m

g) Opening and closing speed: not less than 0.2m / min, not more than 1.5m / min.

h) Bracket distance from the wall ≥ 300㎜, distance from the bottom ≥ 150㎜ ~ 250㎜.

| DN | B | B2 | B1 | G | d1 | E | f | g | i |

| 300 | 300 | 380 | / | 50 | 18.5 | 80 | 416 | 456 | 685 |

| 400 | 400 | 480 | / | 50 | 18.5 | 95 | 516 | 556 | 835 |

| 500 | 500 | 580 | / | 50 | 18.5 | 95 | 616 | 656 | 1060 |

| 600 | 600 | 700 | / | 70 | 24 | 95 | 750 | 790 | 1160 |

| 700 | 700 | 800 | / | 70 | 100 | 850 | 890 | 1260 | |

| 800 | 800 | 900 | / | 80 | 24 | 100 | 960 | 1010 | 1450 |

| 900 | 900 | 1000 | / | 80 | 24 | 115 | 1060 | 1110 | 1600 |

| 1000 | 1000 | 1100 | / | 80 | 24 | 115 | 1160 | 1210 | 1900 |

| 1200 | 1200 | 1300 | 1360 | 90 | 28 | 115 | 1370 | 1430 | 2765 |

| 1400 | 1400 | 1540 | 1570 | 90 | 28 | 115 | 1580 | 1650 | 3315 |

| 1500 | 1500 | 1640 | 1670 | 90 | 28 | 115 | 1680 | 1750 | 3415 |

| 1600 | 1600 | 1740 | 177 | 100 | 28 | 115 | 1780 | 1850 | 3515 |

| 1800 | 1800 | 1940 | 1970 | 100 | 28 | 115 | 1980 | 2050 | 3815 |

| 2000 | 2000 | 2140 | 2180 | 120 | 28 | 135 | 2200 | 2270 | 4150 |

| 2200 | 2200 | 2300 | 2400 | 120 | 28 | 135 | 2400 | 2520 | 4450 |

| 2400 | 2400 | 2500 | 2600 | 150 | 28 | 150 | 2600 | 2750 | 5130 |

| 2500 | 2500 | 2600 | 2700 | 150 | 28 | 150 | 2700 | 2820 | 5250 |