Pneumatic fixed ball valve

Pneumatic fixed ball valve

Nominal diameter: DN50 ~ 500mm

Nominal: PN1.6 ~ 6.4MPa

Temperature: -28 ℃ ~ 300 ℃

Suitable medium: water, steam, oil, nitric acid, acetic

Operation: manual, pneumatic

Structure length by: GB1221-89

Flange size by: GB9113, JB79-59

Test by: JB / T9092-99

Pneumatic fixed ball valve overview

Pneumatic fixed ball valves, pneumatic ball valves, ball valves are two-way valve, the flow of unlimited. The flange is connected with studs, the upper and lower stems are equipped with sliding bearings to reduce friction, the use of labor-saving, smooth. Under normal conditions: when the pressure is low, the valve seat seal relies on the spring pre-tightening force to make the valve seat close to the ball body to seal. When the pressure is high, a piston effect is formed on the valve seat. Under the action of the upstream medium pressure, To seal, fixed pneumatic valve, pneumatic valve, ball valve is widely used in process control system to achieve on or off.

Pneumatic fixed ball valve technical parameters

| Valves | transfer method | Link form | structure type | Sealing surface | Nominal pressure (MPa) | Body material |

| Ball valve | 6-pneumatic 6s-pneumatic band manual | 4-flange | Fixed ball straight | F-Fluoroplastic H-alloy steel PPL | 1.6 2.5 4.0 6.4 | According to the table body material code |

| Nominal diameter DN (mm) | 50-500 | |||||

| Material code | C | P | R | |||

| The main parts | Body | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni12Mo2Ti | ||

| Ball board | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12MoTi | |||

| Valve stem | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12MoTi | |||

| Sealing ring | Enhanced polytetrafluoroethylene alignment poly stupid | |||||

| filler | Polytetrafluoroethylene flexible graphite | |||||

| Fitness with working conditions | Suitable media | Water, steam, oil | Nitric acids | Acetic acid | ||

| proper temperature | -28 ° C to 300 ° C | |||||

| Control type | Double-acting / single-acting | |||||

| The role of type | Cut / adjust | |||||

| input signal | Electrical signal: 0 ~ 10mA, -4 ~ 10mA gas signal 20 ~ 100kPa | |||||

| Reply voltage | AC220V / DC24V | |||||

| Working medium | Purification compressed gas | |||||

| Actuator | model | GT series, HY series, AW series, ZSH series | ||||

| Air pressure | 0.4 ~ 0.7MPa | |||||

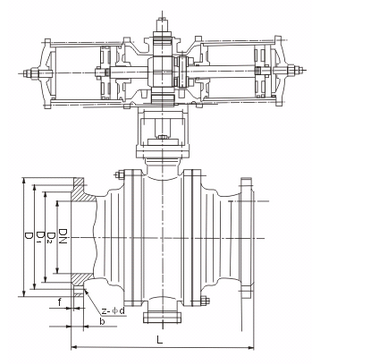

| Nominal diameter DN (mm) | Size (mm) | Actuator model | ||||||||||||||

| 1.6MPa | 2.5MPa | 4.0MPa | ||||||||||||||

| L | D | D1 | B | Z-φD | L | D | D1 | B | Z-φD | L | D | D1 | B | Z-φD | ||

| 50 | 203 | 160 | 125 | 16 | 4-18 | 216 | 160 | 125 | 20 | 4-18 | 216 | 160 | 125 | 20 | 4-18 | Optional GTD / GTE, AW / AWS, HY, ZSH series actuators (the above optional only for the specific election based on actual requirements) |

| 65 | 222 | 180 | 146 | 18 | 4-18 | 241 | 180 | 145 | 22 | 8-18 | 241 | 180 | 145 | 22 | 8-18 | |

| 80 | 241 | 195 | 160 | 20 | 8-18 | 283 | 195 | 160 | 22 | 8-18 | 283 | 195 | 160 | 22 | 8-18 | |

| 100 | 305 | 215 | 180 | 20 | 8-18 | 305 | 230 | 190 | 24 | 8-23 | 305 | 230 | 190 | 24 | 8-23 | |

| 125 | 356 | 245 | 210 | 22 | 8-18 | 381 | 270 | 220 | 28 | 8-25 | 381 | 270 | 220 | 28 | 8-25 | |

| 150 | 394 | 280 | 240 | 24 | 8-23 | 403 | 300 | 250 | 30 | 8-25 | 403 | 300 | 250 | 30 | 8-25 | |

| 200 | 457 | 335 | 295 | 26 | 12-23 | 502 | 360 | 310 | 34 | 12-25 | 502 | 375 | 320 | 38 | 12-30 | |

| 250 | 533 | 405 | 355 | 30 | 12-25 | 586 | 425 | 370 | 36 | 12-30 | ||||||

| 300 | 610 | 460 | 410 | 30 | 12-25 | 648 | 485 | 430 | 40 | 16-30 | ||||||

| 350 | 686 | 520 | 470 | 34 | 16-25 | 762 | 550 | 490 | 44 | 16-34 | ||||||

| 400 | 762 | 580 | 525 | 36 | 16-30 | 838 | 610 | 550 | 48 | 16-34 | ||||||

| 450 | 864 | 640 | 585 | 40 | 20-30 | 914 | 660 | 600 | 50 | 20-34 | ||||||

| 500 | 914 | 705 | 650 | 44 | 20-34 | 991 | 730 | 660 | 52 | 20-41 | ||||||