Selection design and application of ball valve for submarine pipeline

1 overview

With the rapid development of offshore oil and gas industry technology and people's demand for energy, the development of deepwater oil and gas fields will become the focus of the future development of offshore oil and gas industry.The subsea oil and gas production system is less affected by the disaster weather and has strong reliability.Submarine pipeline valve is an important part of underwater oil and gas production system equipment.Based on the practical application of two ball valves (hereinafter referred to as ball valves) in an offshore oilfield production and development project, this paper introduces the type selection design, land test and subsea operation of ball valves in subsea pipelines.

2 common standards

Subsea pipeline valve is the general name of all valves applied in subsea pipeline, which is mainly used in underwater manifold, subsea pipeline terminal and oil and gas transmission pipeline of offshore oil and gas engineering.Subsea pipeline valves are mainly ball valves, flat gate valves and check valves.

API6DSS, API6A, API17D and iso13628-1 are the main standards adopted for submarine pipeline valves.

3 operation mode

The valve operation modes of subsea pipeline mainly include hydraulic control, rov-remoteoperatedvehicle and diver operation.

3.1 hydraulic control

The subsea pipeline valve is integrated into one system with the hydraulic source, hydraulic control unit and umbilical cable, and the control unit with the hydraulic source opens and closes the valve for the pressure supply of the subsea pipeline valve.The advantage of this method is that the valve can be opened and closed automatically, the status of the submarine pipeline valve can be monitored in real time on the offshore oil platform, and the valve can be operated by ROV when the hydraulic control system fails.However, hydraulic control complex, potential leakage points, high investment costs.

3.2 the ROV

ROV interface is set on the valve of subsea pipeline, which is divided into two types: top installation and side installation. The valve is opened and closed by ROV equipped with torque tool.The advantage of this operation mode is that the valve structure is simpler than hydraulic control, the cost is relatively low, can save the cost of project construction stage.However, the ROV operation cannot achieve emergency shutdown when the valve of the subsea pipeline needs to be closed in case of emergency of the offshore oil platform, and the offshore oil platform cannot monitor the status of the valve of the subsea pipeline.

3.3 diver operation

In shallow water, the valves of subsea pipelines are usually equipped with handwheels, which divers can operate by air diving.In addition, for subsea pipeline valves with ROV interface, divers can use special operating tools to operate subsea pipeline valves by saturation diving, if conditions permit.

4 selection design

4.1 main technical indicators

The design service life, design temperature, design pressure, ball valve form, design standard, valve size, pressure grade, valve body material, ball material, ROV interface grade, ROV interface mode, ROV interface standard and valve manufacturing grade are mainly considered in the selection design of ball valve.In addition, attention should be paid to valve base form, ROV handle and its form, distance from ROV center line to valve center line, sea protection device at ROV interface, third-party inspection scope and content, high-pressure water tank test of valve and actuator (affecting cost and delivery time), etc.The purchaser shall clarify the technical details when conducting technical clarification with the supplier to prevent unnecessary contract changes.

4.2 end face connection

The end face connection of the ball valve is in the form of flange connection and butt welding connection (figure 1).

(a) flange connection (b) butt welding connection

FIG. 1 ball valves of submarine pipeline connected with different end faces

When ball valve is connected by butt welding, the potential leakage source of valve can be reduced when flange is connected, and the reliability of pipeline system can be improved.Valve in addition to replacement and maintenance inconvenience, in the operation, weight and price and other aspects of the impact is not big.The design of underwater oil and gas production system should consider the reliability of valve and maintainability.Overall consideration, ball valve should be used in the form of welding.

4.3 sealing form

Ball valve in deep water conditions in addition to bear the pressure in the medium, but also bear the hydrostatic pressure, in order to prevent media leakage or seawater into the body, the body and the environment generally set two seals, metal seal as the main seal.The sealing surface of the valve seat has two forms: single piston effect and DoublePistonEffect.The principle of SPE is that there is a seal area difference between the valve chamber and the upstream sealing surface.When the valve chamber pressure increases to a certain value, the pressure difference between the valve chamber and the upstream is greater than the initial pressure of the spring, thus pushing the valve seat away from the ball, achieving the valve chamber pressure to the upstream release.DPE principle is the valve seat downstream and upstream between the existence of sealing area difference.When the pressure increases in the valve chamber, under the action of pressure difference and spring initial sealing pressure, the seat is pushed to the ball to achieve two-way valve sealing.Ball valve generally requires the use of SPE+DPE seal form, usually the upstream sealing surface of the valve as SPE, so as to achieve the valve chamber when the pressure exceeds the function of automatic upstream discharge.

4.4 sleeves

Sleeves are short joints welded at both ends of valves for welding to subsea pipe terminals or subsea manifices.In order to prevent damage to the sealing of valve body during sleeve welding, it is generally required to complete the welding of sleeve before leaving the factory.At the same time, in order to facilitate the subsequent welding with the pipeline, the sleeve pipe shall be made of the same material as the pipeline.The sleeve length must ensure that the heat generated during welding with the pipe does not affect the sealing performance of the valve.Sleeve tubes can be supplied with material number and requirements by the valve buyer, by the valve manufacturer, or by the valve buyer to the valve manufacturer.After the sleeve pipe and valve are welded, the weld shall be hydraulically tested and witnessed by a third party.

5.Land functional testing

The ball valve must complete the FactoryAcceptanceTest (fat-factoryacceptancetest), which includes appearance test, pressure test and operation function test.In the case of FAT, the buyer's representative and the third party's representative are usually required to witness the site. Before shipment, the valve manufacturer shall provide the FAT report signed by the third party.

The ball valve needs to be welded to the pipeline. After the construction of the whole submarine production system structure, hydraulic and electrical continuity tests are required.The function of the ball valve should also be tested before launching it into the sea.The main purpose is to test the performance of its open and close operation, including rotation direction, torque and number of turns.

6.Subsea operation of ball valve

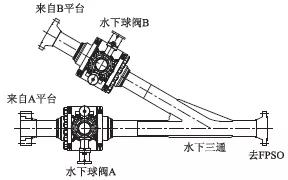

The ball valve A is connected to the pipeline of offshore platform A, and the ball valve B is connected to the pipeline of offshore platform B. The logistics is transferred to the FPSO for processing after joining the three submarine pipelines (figure 2).

FIG. 2 subsea pipeline base plate arrangement

Before launching, the two ball valves are in the open state. After the installation of the subsea pipe base plate, the whole Marine pipe system needs to carry out ball cleaning and hydrostatic test, so the two valves remain open.After the test, platform A is put into production first, so valve A is still in the open state.At this time, platform B is not put into production, so valve B needs to be closed first.When platform B is put into production, open valve B.Therefore, valve B needs to be closed and opened.

The submarine pipeline base plate is installed by divers in the mode of saturated diving. After the pressure test of the Marine pipeline system, divers shall use special tools (FIG. 3) to close the submarine pipeline valve B.

FIG. 2 subsea pipeline base plate arrangement

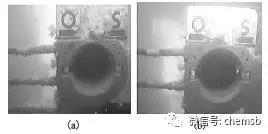

When platform B is put into production, the ball valve B in the closed state shall be opened.At this point, because the saturated dive support vessel has been restored, the ROV is equipped with a torque tool to start it. The ROV should be in working mode and the operating tool is the same as that used in the land test.When the ball valve is closed, the ROV interface pointer points to the letter S.When the ball valve opens, the pointer at the ROV interface points to the letter O (figure 4).

(a) valve in closed state (b) valve in open state

FIG. 4 closed and open state of ball valve of submarine pipeline

7 conclusion

Deep-sea oil and gas exploitation is the development trend of future resource exploitation, and the valve of submarine pipeline is the key component of submarine pipeline manifold and other equipment, which will be more and more widely used.